Blacksmithing

Practical Action

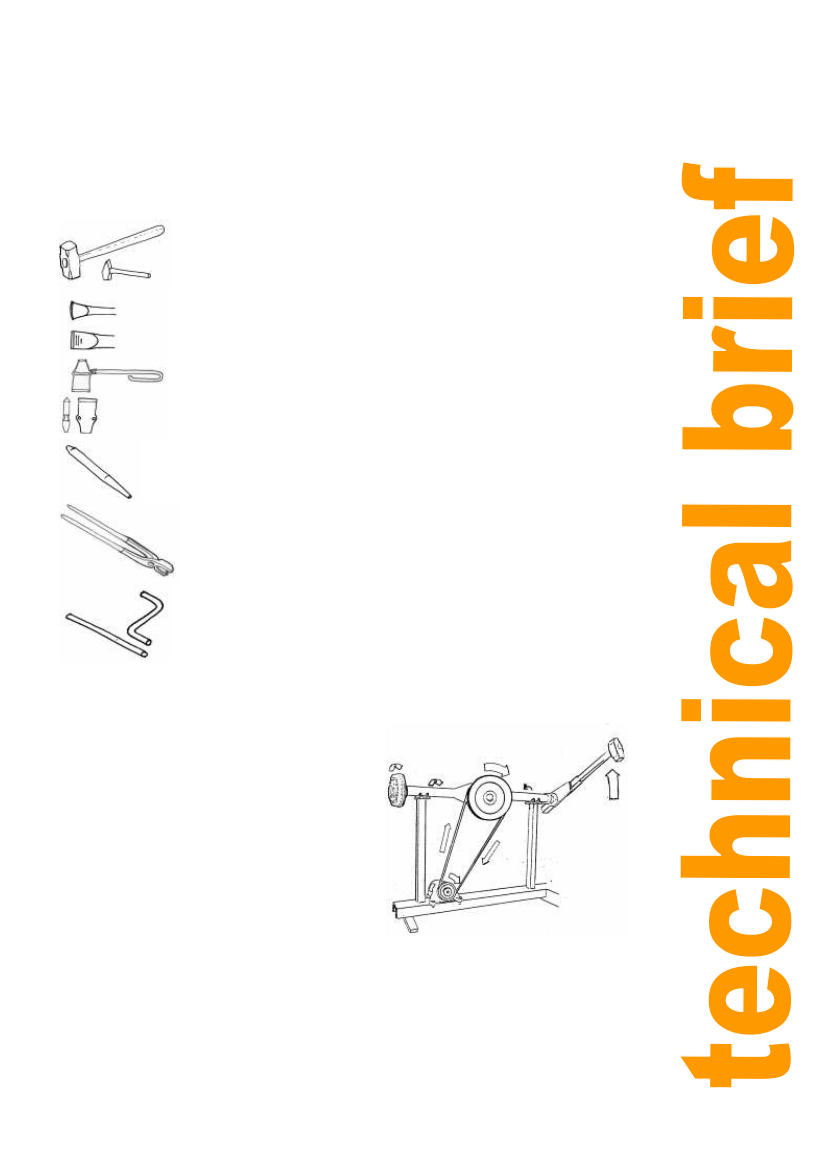

Shaping/ Deforming Tools

All tools to deform malleable iron or steel consist of clams, hot and cold sets, various tongs

for handling the work piece and, of course, hammers. These are illustrated as follows,

Sledge Hammer – Very Heavy hammer usually used by the blacksmiths

assistant to work the large pieces of metal.

Cross Peen Hammer – Smaller hammer with two ends for different effects.

Used in most forging processes.

Hot Chisel – Used for cutting hot metal, by striking with a hammer. This tool

is not hardened and should not be used to cut cold material, only heated.

Cold Chisel – Used to cut cold material, never hot material. This tool is

hardened and tempered so it is sharp and strong so it can cut cold material.

Hot set – Similar to a chisel but with a long handle. It is usually struck by a

sledgehammer operated by the blacksmiths assistant. Not for cold material.

Cold set – This is used for cold material as the name suggests. It again has

a long handle like the hot set. Again it is struck by a sledgehammer. The

cold set looks similar to the hot set apart from its thickness and angle of

blade.

Round Punch – Creates a round hole by driving the punch through a sheet

of hot material. Alternative to the drill.

Tongs – Used to hole material when it has been hated and is ready for

work. These can be made in the forge, for different pieces of work. The

heads can be shaped to grip different sizes and shapes of material.

Bottom Fuller – Normally used with a top filler, to create rounds or indents

in material.

Top Fuller – Used to make grooves in hot metal. Both the top and bottom

fuller can be made from mild steel.

Figure 4: Tools Required

Mechanical Tools

There are many varieties of mechanical tools,

which might be useful amongst which are; a fly-

press, drilling machine, drop hammers and tilt

hammers can be used, powered by a motor or

water

Work Materials

The majority of material used by blacksmiths is

that obtained from scrap yards and old cars.

Sometimes materials may be bought in but often

it is not necessary, as there are other materials,

which can be reused.

Figure 5: A mechanical tilt hammer

using old car components.

4